GABLOK AUSTRALIA – Technical & Structural FAQs

GABLOK AUSTRALIA – Technical & Structural FAQs

What is the wind load rating of your product?

Gablok structures are engineered to comply with AS 4055 (Wind Loads for Housing) and AS/NZS 1170.2 (Structural Design Actions – Wind Actions).

Each project is assessed according to its wind classification (N1–N6 or C1–C4) depending on its geographic location and topography.

The system can be structurally certified up to N3 / C1 classification under standard configuration, and higher ratings (N4–N5) can be achieved with engineering reinforcement and appropriate tie-down specifications. Certification is completed per project by an Australian structural engineer.

Could you please supply the tie-down details for both the roof structure at the roof/wall intersection and the footings?

Tie-down requirements are determined during engineering certification based on local wind ratings and roof type.

Roof-to-wall tie-down:

Uses galvanised steel truss or rafter brackets fixed through the top timber plate anchored directly into the structural Gablok timber core using M12 bolts or equivalent structural screws.Wall-to-footing tie-down:

Utilises galvanised steel anchor rods (M12–M16) cast into the concrete footing/slab, secured with washers and nuts through the bottom timber plate. Anchor spacing typically ranges 1.2–1.8 m depending on engineering requirements.

A complete tie-down schedule is included in the engineering drawings prepared for the Building Approval (BA) stage.

Is the external lining of the block likely to be affected by humidity and flooding rains?

No. Gablok’s insulation core is expanded polystyrene (EPS) with high-density compression and closed-cell structure, meaning it does not absorb water and retains its insulation and structural properties even after direct contact with moisture.

The exterior finish (cladding, render, or weatherboard) acts as the final waterproofing layer.

All components comply with AS/NZS 4859.1 (Thermal Insulation Materials) and AS/NZS 4200.1 (Moisture Control).

How are electrical/data and other services installed?

Services are routed through pre-designed vertical and horizontal chases in the block cavities, or within the internal batten cavity before plasterboard installation.

Conduits for power, water, and data are laid without cutting the structural timber frame, ensuring system integrity.

Switches and outlets are mounted in recessed junction boxes as per AS/NZS 3000 wiring regulations.

How are windows and doors fixed?

Openings are pre-framed during assembly.

Lintels are integrated above each opening using engineered timber beams (LVL or solid timber) designed for load transfer.

Windows/doors are installed using standard Australian fixing brackets (screw or nail type) directly into the surrounding timber frame, sealed with flashing and waterproof membrane to meet AS 2047 (Windows and Glazing) and AS/NZS 4284 (Building Facades).

What would be the approximate cost of a pallet of blocks to ship to Australia, and how many blocks would be on a pallet?

Average weight per pallet: 400–500 kg

Number of blocks per pallet: ≈ 40–50 blocks (depending on block type)

Freight cost (Belgium → Australia): ≈ AUD 1,200–1,800 per pallet (sea freight, excluding customs & GST)

Bulk container shipping (20 ft or 40 ft) significantly reduces unit cost per block, making it 15–25% more efficient than pallet shipping.

How many blocks are there per square metre?

Approximately 6.25 blocks / m², based on a standard full block dimension of 750 mm (L) × 300 mm (H) with 150 mm thickness.

(Exact number varies slightly depending on wall configuration and corner details.)

What are the dimensions of a full, half, and corner block?

Block TypeDimensions (L × H × W)Approx. WeightDescription

Full Block750 mm × 300 mm × 150 mm 7.5 kg Standard structural block

Half Block375 mm × 300 mm × 150 mm 3.7 kg Used for staggered joints

Corner Block750 mm × 300 mm × 150 mm 7.5 kg Includes 90° interlock

Top Plate / U-Block750 mm × 300 mm × 150 mm 7.0 kg Used for lintels, bond beams, or service runs

Can self-build blocks be used to build any size house?

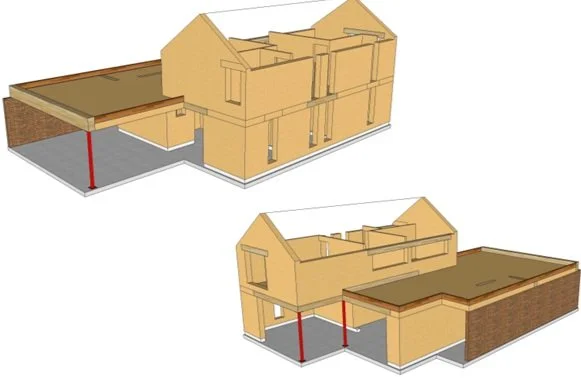

The Gablok self-build system has been designed to form the frame of most structures with the insulated wooden blocks designed to fit together to form the main structure of a residential building. When drawing up the plans for your Gablok home, we conform as closely as possible to the developer’s needs so that you can build your dream home house with ease.

We also adapt the design plans to suit the type of finish needed, whether that be cladding, brick veneer or render. Also, the dimensions of door and window openings are established in advance so you’re able to order the necessary components to install directly after the construction of the structural work is completed.

Does assembling the wooden blocks keep my self-build level?

The Gablok wood frame self-construction system is currently being studied for a two-storey building, and we are currently evaluating the effectiveness of the system for 3-storey building construction.

When the starting rail is properly placed level, the assembly of insulated wooden blocks will be perfectly vertical up to the second-floor level as our self-build blocks are calibration to a tolerance of 0.5 mm.

How is the structure of the self-built wooden frame fixed to the ground?

The wooden structure of the self-build is fixed to the concrete slab using anti-tear brackets. Then all you have to do is follow the plan (that is provided to you on site with the pallet of insulated wooden blocks).of the structure to complete your self-build.

What about the wood quality of the insulating wood blocks?

The wood used for the Gablok wooden construction elements is 18mm thick OSB, which is a mixture of natural resin and wooden strips (chips). The specificity of OSB is that the wood that composes it is ultra-compressed which prevents it from moving and distorting over time.

For the construction of a floor, can we have beams or a concrete overlay on top of the insulated wooden blocks?

With Gablok, all self-constructions are made from the same insulated wooden elements. Among these, we have our own floor system, especially designed so that it is not necessary to cover it with a concrete screed. We provide all the beams and lintels needed to create your floors. In the Gablok self-construction kit, you will find wooden beams capable of supporting very long spans.

What are the spans of wooden lintels, beams and floor elements of Gablok frames?

We call lintels the wooden elements that serve as closures and make up the floors and ceilings above the doors and frames of our wooden frame self-constructions. The longest lintels in our kit are 240cm long. The beams have a large span, which allows them to support all construction projects (house, annex, extension, etc.). The floor elements can support a span of 4.8M, this span can however be increased by adding beams.

The total span of a timber frame structure built of Gablok has values equal to that of a traditional house. For the compressive strength of a wall made of insulated wooden blocks made of Gablok, we speak of a resistance of 150 kN/m. Regarding the payload, the elements that make up the boards allow a load of about 250 kg/m².