THE VERY BEST IN EUROPEAN DIY SUSTAINABLE DESIGN & CONSTRUCTION

ELEMENTS

Build your dream home, block by block with your own hands, saving you time, money and taking years off your mortgage. Contact us today to discuss your dream home project.

Designed in Belgium.

INVEST IN gablok Australia.

Our system is an owner-builders dream, and its child’s play to build.

owner-builders dream

We’re a company that believes in giving you the tools, training and support you need to build your dream home with your own hands. That’s why our modular timber block construction system has been designed specifically to meet the needs of DIY owner-builders, enabling everyday people to take control of their home building project to save time and money by being an active part of the construction of their dream homes.

Our system is an owner-builders dream, and its child’s play to build. Our system is comprised of just a handful of portable components delivered as a flat-pack construction system with step-by-step plans. Construction involves connecting the modular timber blocks together by hand, laid directly on to a concrete slab, enabling DIY builders to construct the exterior and interior walls, floor and ceiling of their homes by hand in a matter of days, not weeks.

The Chevron brace

The chevron braces provide lateral-load resistance for the house frame, holding the entire prefab home together.

Floor element

The floor components fit onto the top plate and forms the floor or roof support structure of the building.

Support beam

The beam is designed to support heavy spans and weight loads and is used to hold the storeys of the building together.

Belt blocks

The insulated belt blocks are used for the top of walls to accommodate an embossed plate which either the next floor or roof structure sit on top of.

300mm width

300mm height

600mm length

Insulated blocks

The “traditional” insulated wooden block is the most commonly used component in a self-build. It is available in 3 formats to suit a range of sizes and applications.

300mm width

300mm height

600mm length

Isolated starting block

The insulated bottom block will be the first layer of blocks laid directly onto the AAC concrete blocks that lay on top of the slab to act as a moisture barrier.

300mm width

300mm height

600mm length

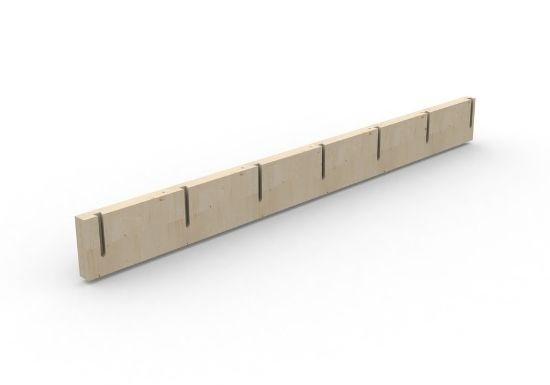

Start and top rails

The wooden plates serve as a base for the self-build and connect the belts of blocks.

Lintel

The lintel is used above window frames and door openings to support weight.

300mm width

300mm height

1500mm - 30000mm length

Detailed plans

Every home comes complete with step-by-step construction plans for simplicity.