Here are some short and sweet answers to common questions...

What does the Gablok wooden house self-build kit include?

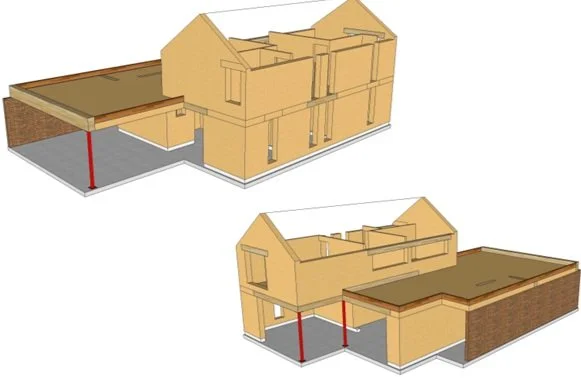

The Gablok system includes all the individual elements required to build the frame of your house, including interior load-bearing walls and the exterior structure of your home. The wooden self-build blocks are delivered to your site on bonded pallets, saving you the waste associated with on-site shaping, and making the construction process fast whilst keeping your site clean throughout the duration of the self-construction process.

Self-construction with Gablok does not require drying time, you simply assemble and fix the blocks using the step-by-step plans that is provided to you at the same time as the blocks. The Gablok team also provides initial training in our DIY construction method and will be there to provide ongoing technical assistance as required. When the structure of your house frame is finished, all you have to do is build the complete roof and carry out the finishing touches (doors, windows, bathrooms etc.).

The wood frame self-build kit in detail.

Our wood frame self-construction kit is made up of just 8 elements:

1. General insulated blocks

2. Isolated starting blocks

3. The connecting elements

4. Belt wooden blocks

5. Start and top rails

6. Floor elements

7. Lintels

8. Beams

In addition to these 8 components, you will also receive all the necessary screws and fittings to construct your frame from the plan.

Can self-build blocks be used to build any size house?

The Gablok self-build system has been designed to form the frame of most structures with the insulated wooden blocks designed to fit together to form the main structure of a residential building. When drawing up the plans for your Gablok home, we conform as closely as possible to the developer’s needs so that you can build your dream home house with ease.

We also adapt the design plans to suit the type of finish needed, whether that be cladding, brick veneer or render. Also, the dimensions of door and window openings are established in advance so you’re able to order the necessary components to install directly after the construction of the structural work is completed.

How do the different insulated wooden blocks fit together?

No jointing system is required for self-building with Gablok blocks because the wooden blocks fit together like interlocking building block toys to form the structure of the house. The individual insulated wooden blocks of the outer walls are secured together by a system of vertically laid battens. When a storey is finished, these battens - attached vertically every 40 cm - support not only all the blocks forming the floor but also the bottom plate and the embossed top plate with the screws provided. When a wall is finished, a second plate (the embossed plate) is inserted into the last stack (Blocks under ceiling or insulated belt blocks). This acts as a belt and support for installing the floor components.

What type of insulation is used in our self-build blocks?

Among all the insulators available, Gablok has made the choice of expanded polystyrene with graphite additive (EPS) for its building system.

EPS is about 98 % air. The remaining 2 % is material derived from oil refining. EPS gives a second life to this material that could not have been used as a fuel. EPS remains stable over time, it has no negative impact on the environment and it is neither toxic nor polluting.

EPS is environmentally friendly and has a high-performance insulation system. The carbon footprint of a traditional house or timber frame insulated with EPS will be superior to that of a masonry construction. EPS requires less transport given its small size (the beads increase their volume by 40 times their size into contact with water vapour without solvents or other adhesives) and takes up less space. Because of its expanding capacity, it does not use considerable amounts of water and energy to increase its shape.

EPS is a recycled and recyclable product. An alloy of wood and EPS is manufactured for impressive performance. The EPS insulation designed for Gablok insulated wooden blocks is combined with OSB formwork. The blending of wood and EPS allows Gablok constructions to benefit from a very interesting insulating value and energy performance.

What is Gablok’s energy performance, thermal insulation, and EPB?

The EPB is examined on a case-by-case basis, depending on the site. The energy performance of buildings (EPB) is calculated according to a number of specific criteria, the value of which differs according to the type of dwelling. These criteria correspond to the dwelling’s defining characteristics.

For example: the different types of insulation used (roof, external walls, internal walls, etc.), the type of window frames and surface, the orientation of the house, and the heating system proposed. The thermal conductivity (“U” value) of a wall built with Gablok is 0.15 w/sqm²k. The insulated wooden blocks are suitable for 2021 EPB values. Today, the thermal conductivity required by the EPB for a wall is U = 0.24 w/m²k , without applying additional external insulation when the thermal conductivity of a passive house wall is U = 0.10 w/m²k.

Why are Gablok Insulated wooden blocks suitable for self-construction?

Given their shape, Gablok self-build blocks are directly inspired by insulating formwork block in that the two types of building blocks form the formwork (the structure) of the dwelling. The two kinds of insulating blocks allow insulation, stability, verticality, sealing and neat finishes without the need for large tools. What primarily differentiates Gablok insulated wooden blocks from site formwork blocks is their composition. The structure of the traditional formwork blocks is made, in most cases, of concrete. Once assembled to form the walls of the building, cement is poured inside to stabilize the blocks. In the case of insulating shuttering blocks made of expanded polystyrene, cement is also poured inside the blocks when they are put in place. Steel bars can be added to reinforce the structure.

The Gablok concept comprises the structure of our insulated blocks is made from OSB wood (a stable sustainable wood) and the EPS (expanded polystyrene) insulation is directly integrated into the wooden block with no chemicals added inside. This EPS comes in the form of beads expanded in contact with heat to form insulation blocks that are inserted into the wood block allowing optimal thermal insulation while preserving the environment as the material does not require great resources, plus it’s light and therefore easily transportable. Unlike insulating formwork blocks, the advantage of Gablok insulated wooden blocks is that their weight does not exceed 9kg. This makes them ideal for self-construction of your project!

Once manufactured in our factory, you receive the entire framing structure on pallets on site containing the exact number of blocks needed for your project. Then all that remains is to follow the plan provided, assemble the wooden blocks like in a construction game, and then fix everything using the rafters provided.

Does assembling the wooden blocks keep my self-build level?

The Gablok wood frame self-construction system is currently being studied for a two-storey building, and we are currently evaluating the effectiveness of the system for 3-storey building construction.

When the starting rail is properly placed level, the assembly of insulated wooden blocks will be perfectly vertical up to the second-floor level as our self-build blocks are calibration to a tolerance of 0.5 mm.

How is the structure of the self-built wooden frame fixed to the ground?

The wooden structure of the self-build is fixed to the concrete slab using anti-tear brackets. Then all you have to do is follow the plan (that is provided to you on site with the pallet of insulated wooden blocks).of the structure to complete your self-build.

What about the wood quality of the insulating wood blocks?

The wood used for the Gablok wooden construction elements is 18mm thick OSB, which is a mixture of natural resin and wooden strips (chips). The specificity of OSB is that the wood that composes it is ultra-compressed which prevents it from moving and distorting over time.

For the construction of a floor, can we have beams or a concrete overlay on top of the insulated wooden blocks?

With Gablok, all self-constructions are made from the same insulated wooden elements. Among these, we have our own floor system, especially designed so that it is not necessary to cover it with a concrete screed. We provide all the beams and lintels needed to create your floors. In the Gablok self-construction kit, you will find wooden beams capable of supporting very long spans.

What are the spans of wooden lintels, beams and floor elements of Gablok frames?

We call lintels the wooden elements that serve as closures and make up the floors and ceilings above the doors and frames of our wooden frame self-constructions. The longest lintels in our kit are 240cm long. The beams have a large span, which allows them to support all construction projects (house, annex, extension, etc.). The floor elements can support a span of 4.8M, this span can however be increased by adding beams.

The total span of a timber frame structure built of Gablok has values equal to that of a traditional house. For the compressive strength of a wall made of insulated wooden blocks made of Gablok, we speak of a resistance of 150 kN/m. Regarding the payload, the elements that make up the boards allow a load of about 250 kg/m².